Custom Trailer Manufacturing Solutions Built for Your Industry

Specializing in custom trailer frames and OEM manufacturing for diverse industries worldwide.

Why Choose Zhuoyue Metal for Trailer Manufacturing?

At Zhuoyue Metal, we understand the challenges and hesitations customers may have when searching for a reliable trailer manufacturing partner. From product quality to delivery timelines, we provide comprehensive solutions to meet your needs with confidence and precision.

1. Is the Product Quality Reliable?

We uphold the highest standards of quality in every step of the manufacturing process. With advanced equipment and strict quality control protocols, our trailer frames and components are built to last.

Key Features:

- Certified Quality Assurance: ISO-certified processes ensure each product meets industry standards.

- State-of-the-Art Equipment: Laser cutting and robotic welding guarantee precision and durability.

- Material Excellence: Using premium-grade metals like Q235B and Q345B for superior strength.

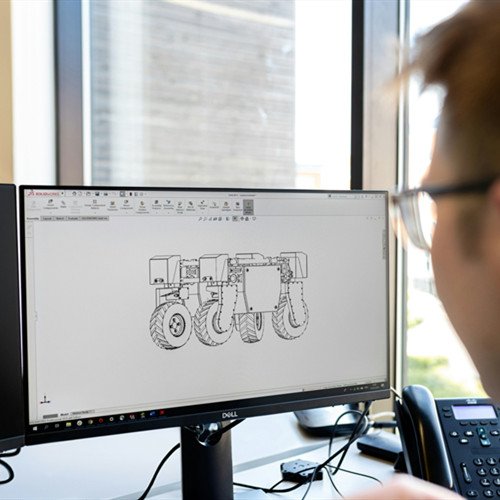

2. Can You Provide Custom Solutions?

Yes! We specialize in custom trailer manufacturing to meet specific industry needs, from cargo trailers to RV and agricultural equipment frames.

Key Features:

- Tailored Designs: Our engineers collaborate with you to design and prototype custom solutions.

- Flexible Manufacturing: From small-batch prototypes to large-scale production, we adapt to your requirements.

- Versatile Applications: Products suitable for trailers in logistics, agriculture, and recreation.

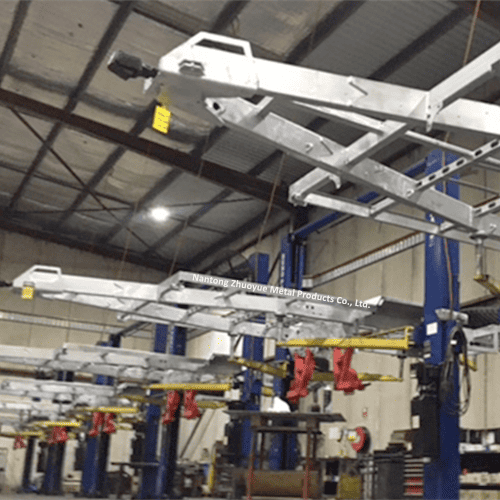

3. Can You Meet My Delivery Deadlines?

With efficient production processes and a dedicated team, we ensure timely delivery for all orders.

Key Features:

- Streamlined Operations: Five production lines optimize efficiency for fast turnaround.

- Order Transparency: Real-time updates on production and delivery schedules.

- Global Shipping Expertise: Reliable logistics partners ensure smooth international delivery.

4. Is the Pricing Transparent and Reasonable?

We offer competitive pricing without compromising on quality, with clear communication at every step.

Key Features:

- Transparent Quotations: Get a detailed breakdown of costs before production begins.

- Cost-Effective Solutions: Durable products reduce maintenance and replacement expenses.

- Flexible Packages: Standard or customized options to fit your budget and requirements.

Visual Aid:

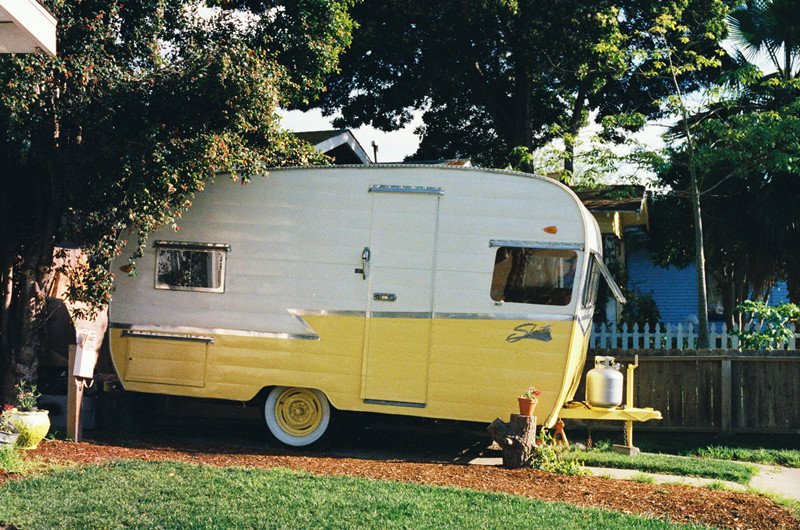

5. Do You Understand My Industry-Specific Needs?

We have extensive experience serving various industries, ensuring tailored solutions for specific applications.

Key Features:

- Industry Expertise: Expertise in trailer manufacturing for logistics, RVs, and agricultural machinery.

- Field-Tested Products: Components designed for real-world conditions and durability.

- End-User Focus: Practical designs that enhance usability and performance in every application.

6. Is Zhuoyue Metal a Trustworthy Partner?

Our track record of successful projects and satisfied clients worldwide speaks for itself.

Key Features:

- Global Reach: Trusted by clients in North America, Australia, and beyond.

- Proven Reliability: Testimonials and case studies available to showcase past successes.

- Professional Team: Experienced technicians and engineers dedicated to your success.

7. How Easy Is the Installation and Maintenance?

We simplify installation with user-friendly designs and provide ongoing support for maintenance.

Key Features:

- Clear Documentation: Detailed installation manuals and guides included with every product.

- Post-Sale Support: Responsive technical support for troubleshooting and maintenance.

- Durable Construction: Products designed for low maintenance and long life.

Ready to partner with a trusted trailer manufacturer?

Contact us today for a customized solution that fits your needs!

Custom trailer plans are crucial in trailer manufacturing, tailored to meet the specific needs of businesses and individuals. Whether it’s for transporting goods, recreational vehicles, or industrial machinery, having a trailer built to exact specifications ensures maximum efficiency, safety, and durability. This guide delves into three critical components in designing custom trailers: trailer frames, trailer jacks, and trailer parts. Each plays a pivotal role in trailer performance and longevity, underscoring the importance of understanding their significance when developing a custom trailer plan.

Table of Contents

I. Trailer Frames: The Backbone of Your Trailer

Understanding Trailer Frame Design

At the core of every trailer lies the trailer frame, serving as its structural foundation that supports the load, bears the weight, and maintains the trailer’s shape and integrity over time. Custom trailer frames are meticulously designed to align with the trailer’s intended use, the types of loads it will transport, and the environmental conditions it will encounter. Manufacturers utilize a variety of materials, such as steel and aluminum, to craft durable frames that effectively balance factors like strength, weight, and cost.

Types of Trailer Frames

There are various types of trailer frames, each suited to different needs:

- Open C-Channel Frames: These frames are known for their strength and durability. They are often used in heavy-duty trailers where weight distribution is critical.

- Tubular Frames: These closed, hollow frames provide excellent protection against corrosion and rust, making them ideal for trailers exposed to the elements.

- I-Beam Frames: These are often used for industrial and commercial trailers, as they provide excellent load-bearing capacity.

The selection of a frame for a custom trailer plan primarily hinges on the cargo weight, road conditions, and intended use. For instance, recreational trailers may prioritize lightweight design, while industrial trailers necessitate high-strength steel frames to support heavier loads.

Material Selection: Steel vs. Aluminum

When choosing a frame material, two primary options are available: steel and aluminum.

- Steel Frames: Known for their robustness and resilience, making them well-suited for heavy-duty uses. Steel exhibits resistance to bending and warping even under substantial loads, rendering it a prime option for trailers transporting industrial equipment, construction materials, and other weighty merchandise. Nevertheless, steel frames may tend to be weighty and susceptible to corrosion if not adequately safeguarded with protective coatings.

- Aluminum Frames: Offered a substantial weight advantage over steel, making them highly suitable for applications prioritizing fuel efficiency and ease of handling. Additionally, aluminum’s resistance to rust provides a significant advantage for trailers utilized in wet or humid environments. Although aluminum is not as robust as steel, it is commonly reinforced with supplementary support elements to enhance durability.

Customization Options for Trailer Frames

Tailoring the trailer’s performance to specific requirements, enabling manufacturers and businesses to customize trailer frames to their preferences:

- Length and Width Adjustments: Depending on the size of the cargo, custom trailer frames can be designed to accommodate larger or smaller loads.

- Additional Reinforcements: For trailers that carry extremely heavy or delicate loads, adding extra support beams or cross-members can help distribute the weight more evenly.

- Modular Frame Designs: This allows for easier repairs and maintenance, as specific parts of the frame can be replaced without needing to overhaul the entire structure.

II. Trailer Jacks: A Critical Support Mechanism

The Function of Trailer Jacks

Trailer jacks play a crucial role in custom trailer designs by providing vital support when the trailer is stationary. They aid in maintaining the trailer’s level and stability, whether loaded or unloaded. Their significance is particularly pronounced during the loading and unloading process, as they mitigate the risk of tipping or shifting, thereby averting potential damage or injury.

Types of Trailer Jacks

Choosing the suitable trailer jack is paramount in the design of a custom trailer plan. There are several different types of trailer jacks to consider:

- A-frame Jacks: Typically found in utility and recreational trailers, are mounted at the trailer’s front to lift and provide support during hitching and unhitching.

- Swivel Jacks: Usually affixed to the trailer’s side, offer the flexibility to swivel out of the way when not in use, making them well-suited for trailers requiring a low profile during transit.

- Drop-Leg Jacks: Commonly employed in heavy-duty trailers, provide adjustable height capabilities, making them well-suited for uneven terrain. These jacks can swiftly drop into place for rapid deployment.

- Electric Jacks: Offer the convenience of automatic trailer raising and lowering at the push of a button, presenting an ideal solution for larger, heavier trailers where manual operation would be challenging.

Capacity and Lift Range

When selecting a trailer jack, it is crucial to factor in both the weight capacity and lift range. The jack must be capable of supporting the trailer’s total weight when loaded, necessitating a match between the jack’s capacity and the trailer’s gross vehicle weight rating (GVWR). Additionally, the lift range is essential, as the jack must be able to raise the trailer sufficiently to clear the hitch.

Importance of Custom Trailer Jacks

Custom trailer jacks can be designed to meet specific needs. This is especially useful for trailers that will be used in unique conditions, such as off-road terrains or commercial settings where frequent loading and unloading occur. Customizing the jack can include options for:

- Heavy-duty capacities for industrial use

- Corrosion-resistant finishes for marine trailers

- Electric or hydraulic operation for ease of use

- Multiple mounting positions to accommodate unique trailer designs

III. Trailer Parts: Essential Components for Functionality and Safety

Key Trailer Parts for Custom Plans

Apart from frames and jacks, trailer parts are integral to overseeing the efficient and secure operation of a custom trailer. These parts encompass an array of components, including axles, brakes, lighting, and hitch elements, all of which demand meticulous selection based on the trailer’s intended use.

1. Axles and Suspension

Axles are crucial trailer parts, serving to uphold the weight of the trailer and cargo. The selection of suitable axles hinges on the trailer’s load capacity and the terrain it will traverse. Common axle types include:

- Straight Axles: Standard axles that are strong and durable, commonly used in utility and cargo trailers.

- Torsion Axles: These provide a smoother ride by using rubberized components to absorb shock, making them ideal for trailers carrying sensitive or fragile loads.

Suspension systems also contribute to the trailer’s overall performance. Leaf spring suspensions are prevalent in heavy-duty trailers, whereas torsion suspensions provide a smoother ride for lighter loads.

Braking Systems

A well-functioning braking system is essential for the safety of the trailer and its cargo. There are two main types of trailer brakes:

- Electric Brakes: These are controlled by the towing vehicle’s brake controller, allowing for smooth and precise braking.

- Surge Brakes: Hydraulic surge brakes are commonly used in boat trailers. They activate automatically when the towing vehicle slows down, offering a hands-off approach.

ZY Trailer Suspension

2. Lighting and Electrical Components

Adequate lighting is not only a legal obligation but also indispensable for safety. Custom trailers often require specialized lighting setups, including:

- LED Trailer Lights: Known for their durability and brightness, LED lights are a common choice for custom trailers. They offer better visibility and last longer than traditional incandescent bulbs.

- Wiring Harnesses: A reliable wiring system is crucial for connecting the trailer’s lights and electrical components to the towing vehicle.

3. Hitches and Couplers

The connection between the trailer and the towing vehicle is established through the hitch and coupler, underscoring their crucial role in ensuring safe operations. Tailored trailers may necessitate specific hitches designed to accommodate the size and weight of the load. For heavy-duty trailers, gooseneck hitches are often preferred as they provide enhanced stability for larger loads, whereas smaller utility trailers may suffice with a ball hitch.

Conclusion

Creating a custom trailer plan involves careful consideration of several critical components: trailer frames, trailer jacks, and trailer parts. By understanding the unique requirements of your business or personal use case, and selecting high-quality, customized components, you can design a trailer that meets all of your needs in terms of performance, safety, and longevity.

Whether you’re looking to transport goods across long distances or haul equipment to a worksite, ZHUOYUE METAL PRODUCTS can help you create a customized trailer solution that offers durability, efficiency, and value. For more information on how to start your custom trailer project, contact us at inquiry@sheetmfg.com or visit our website at https://sheetmfg.com.