Custom RV Frames and Components for Unmatched Adventures

High-performance RV frames and parts tailored for ultimate durability and comfort on the road.

Table of Contents

Looking to elevate your camper trailer performance with a stronger, lighter frame? You’ve come to the right place…

What are RVs?

RVs stands for Recreational Vehicles — mobile living spaces designed for travel, camping, and off-grid adventures. They combine transportation and temporary living quarters, making them popular for road trips, outdoor recreation, and even full-time living.

Common Types of RVs:

Motorhomes (Class A, B, and C): Vehicles with built-in engines and living quarters.

Travel Trailers: Towable units attached to a car or truck.

Fifth-Wheel Trailers: Larger towable RVs with a gooseneck hitch.

Truck Campers: Mounted on the bed of a pickup truck.

Off-Road Campers: Rugged trailers or vehicles designed for tough terrain and remote locations.

For more detailed types, please refer to these articles.

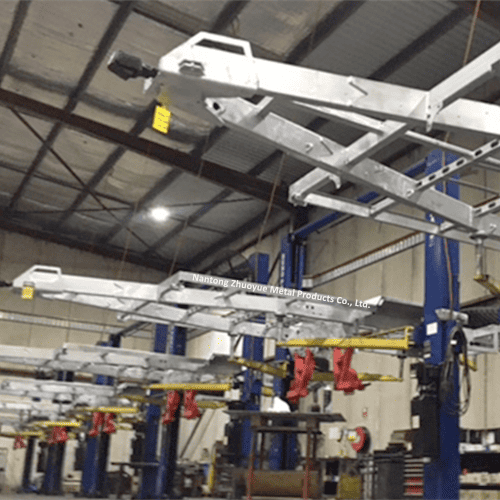

Reliable Manufacturing for Reliable Journeys

At Zhuoyue Metal, we understand that an RV is more than just a vehicle; it’s a gateway to unforgettable journeys and unmatched freedom. That’s why we specialize in manufacturing high-quality RV frames and components designed to support your adventures—wherever the road takes you.

Built for Durability, Designed for Adventure

With over a decade of expertise in metal fabrication, Zhuoyue Metal provides precision-engineered RV solutions trusted by manufacturers worldwide. Whether you’re building travel trailers, fifth wheels, or custom RVs, we deliver durable, lightweight frames and components tailored to your specific needs.

- Superior Quality: Made from high-strength steel and aluminum for longevity and performance.

- Custom Solutions: Designed to fit any RV design or specification.

- Global Expertise: Trusted by leading RV manufacturers across North America, Australia, and Europe.

Explore Our Range of RV Solutions

Start Your RV Journey with Zhuoyue Metal Today!

Explore the world with reliable RV solutions built to last.

Precision Engineering and Reliable Manufacturing

Custom RV Chassis Fabrication for Travel, Fifth Wheel, and Off-road Use

High-level Material

Laser Cutting

Metal Forming

Robot Welding

Surface Finishing

Quality Control

The Team Driving Precision in RV Frame Fabrication

D&R Department

Production Workshop

Assembly Workshop

QC Department

Sales Department

After-sale Department

Frequently Asked Questions (FAQs)

🧱 Chassis & Suspension

Q1: What types of RV chassis do you manufacture?

We provide chassis for travel trailers, fifth wheels, off-road campers, and custom builds — all engineered for strength and compliance with global towing standards.

Q2: Are your independent suspension systems compatible with off-road use?

Yes. Our 3T and 3.5T kits are designed specifically for off-road RVs, with reinforced control arms and extended travel distance.

Q3: Can your suspension systems be retrofitted to existing RVs?

In most cases, yes. We can modify or adapt kits based on your current frame design.

⚙️ Customization & Components

Q4: Can I customize my RV chassis for size, towing type, or load capacity?

Absolutely. We offer fully custom chassis designs including gooseneck, bumper pull, and high-load specs.

Q5: Can I purchase accessories like brackets or jacks separately?

Yes. We supply individual components such as rear bars, bumpers, stabilizers, and storage solutions.

🏗️ Materials & Fabrication

Q6: What materials are used for your chassis and components?

Our standard materials include Q235B, Q345B, 45# steel, and 6061 aluminum — with galvanizing or powder coating available.

Q7: What welding and surface finishing options do you provide?

We use MIG/TIG welding and offer hot-dip galvanizing, powder coating, and anodizing per customer needs.

🚚 Orders & Support

Q8: What’s the typical MOQ and lead time?

Minimum order quantity is 50 units. Typical production lead time is 25–35 days.

Q9: Do you provide international delivery and customs support?

Yes. We export globally and can assist with customs documentation and freight coordination.

Q10: Can you assist with design or prototyping for new models?

Yes. Our engineering team provides full DFM support, CAD review, and prototyping services.

Still Have Questions?

Let us help. Whether it’s a technical challenge or a bulk order inquiry, our engineering and sales teams are ready to assist.

Integrated Solutions for Camper Trailer & Caravan Manufacturers

Whether you’re building rugged off-road campers or luxury caravans, Zhuoyue Metal offers a complete metal fabrication solution — from heavy-duty chassis to precision components — tailored for OEM trailer success.

🔧 Why the Right Chassis Partner Matters

Your trailer’s strength, safety, and long-term performance start at the frame. Our custom RV chassis are:

🔩 Engineered for Strength – Built with high-tensile steel and robust welds

🌐 Tailored for Global Markets – Compliant with AU, US, EU standards

🛠️ Custom-Fit to Your Design – Fully configurable by size, weight, towing style

We don’t just supply a frame — we build your foundation for reliability.

⚙️ One-Stop Metal Fabrication for RV Builders

From concept to container, we deliver everything you need in one shipment:

✅ Chassis & Suspension Systems – Independent, leaf spring, and off-road kits

✅ Brackets & Mounts – Jacks, rear bars, step frames, toolbox supports

✅ Body Components – Lockers, aluminum storage boxes, rear bumpers

With in-house welding, CNC, surface coating, and assembly prep, your production becomes faster, easier, and leaner.

📐 Designed for Your Production Line

We support both low-volume custom runs and high-volume serial production:

⚙️ MOQ from 50 units

⏱️ Lead times: 25–35 days typical

📦 Bundled deliveries: frames + accessories + hardware

🧪 Coatings available: powder coating, hot-dip galvanizing, anodizing

Need reverse engineering? Just send us a sample or CAD — we’ll take care of the rest.

💼 Why OEM RV Manufacturers Choose Zhuoyue

🧲 Consistent Quality Control – Strict QC across all fabrication stages

🌎 Global Export Expertise – Supplying brands in Australia, North America, and Europe

🔄 Cost-Efficient Consolidation – Fewer suppliers, lower logistics costs

🧰 Engineering Support – From prototyping to full-scale rollout

📩 Start Your Next Trailer Build with Confidence

From chassis frames to complete component kits, Zhuoyue Metal helps you reduce complexity and build trailers that perform.