Choosing the Right Mast Materials and Power Types for Public Transport Equipment: A Comprehensive Guide

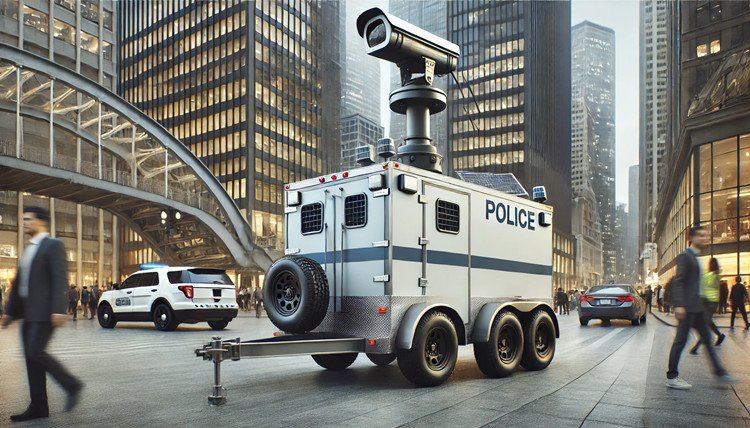

Understanding the Importance of Mast Materials and Power Types in Public Transport

Masts play an essential role in public transport equipment, supporting critical components like cameras, lighting, and signaling systems. These towering structures are not just vital for the functionality of the systems they support but also influence the safety, efficiency, and overall performance of public transportation networks. The materials used in mast construction and the type of power system employed can significantly affect the mast’s durability, ease of operation, and maintenance requirements. In this article, we will explore the different mast material options and power systems, helping you make an informed decision about which combination best suits your needs.

Mast Material Selection: Key Considerations

Mast materials must be carefully chosen to ensure they can withstand the environmental challenges they face while also supporting the required equipment without compromising safety. Below are the most commonly used materials:

Steel Masts: High Durability and Load-Bearing Capacity

Steel masts are widely used for their excellent load-bearing capabilities and overall durability. These masts can support heavy equipment such as surveillance cameras, floodlights, and signal systems. Steel is highly resistant to impact and wear, making it suitable for harsh environments, such as extreme weather conditions or industrial areas. However, steel masts are prone to rusting over time, especially in coastal or humid environments, which can reduce their lifespan unless properly treated or maintained.

Advantages of Steel:

- High load-bearing capacity.

- Strong and durable in extreme conditions.

- Suitable for large-scale installations.

Disadvantages:

- Susceptible to rust if not adequately maintained.

- Heavy, requiring more complex installation.

Aluminum Masts: Lightweight and Corrosion-Resistant

Aluminum masts are a popular choice for lighter applications. They are significantly lighter than steel, making them easier to transport and install. Aluminum is naturally resistant to corrosion, even in moist or coastal environments, making it a preferred choice in areas where rusting could be a concern. However, aluminum masts are typically less robust than steel and are better suited for moderate load-bearing situations.

Advantages of Aluminum:

- Lightweight and easy to install.

- Highly resistant to corrosion.

- Ideal for medium to light-load applications.

Disadvantages:

- Not as strong as steel, limiting its use for heavy equipment.

- May require more frequent checks for structural integrity.

Composite Material Masts: The Future of Mast Design

Composite materials, such as fiberglass, are emerging as strong contenders in mast construction. These materials combine the strength and durability of traditional materials with the lightweight, corrosion-resistant properties of modern composites. Composite masts are increasingly being used in a variety of applications, especially where weight and resistance to environmental factors are paramount. They offer high durability, low maintenance, and long-lasting performance without the rust issues that can affect steel masts.

Advantages of Composite Materials:

- Corrosion-resistant and long-lasting.

- Lightweight yet strong.

- Requires minimal maintenance.

Disadvantages:

- Higher initial cost compared to steel and aluminum.

- May not be as widely available or easily repaired.

Power Type Selection: Understanding the Different Mast Power Systems

The power system you choose for your mast will determine how easily and efficiently it can be adjusted, particularly when dealing with multiple devices and heavy loads. There are four main types of mast power systems:

Manual Masts: Simple and Cost-Effective

Manual masts are the simplest and most cost-effective solution. They are operated by hand, typically through a crank or winch system. While manual masts are easy to operate and require minimal maintenance, they are best suited for installations where frequent adjustments are not necessary. Manual masts are commonly found in low-cost, smaller public transportation setups or areas where mast adjustments are infrequent.

Advantages of Manual Masts:

- Simple design and operation.

- Low initial cost.

- Minimal maintenance required.

Disadvantages:

- Labor-intensive operation.

- Limited in capacity for frequent adjustments.

Electric Masts: Ideal for Frequent Adjustments

Electric masts are perfect for environments where the mast needs to be adjusted regularly, such as in dynamic transportation hubs or areas with varying lighting and camera requirements. Electric masts can be operated at the push of a button, making them more convenient for operators. However, they tend to have higher installation and maintenance costs than manual masts.

Advantages of Electric Masts:

- Easy to operate with minimal human effort.

- Perfect for frequent adjustments.

- More automated and efficient.

Disadvantages:

- Higher installation and operational costs.

- Requires electrical infrastructure.

Pneumatic Masts: Quick and Stable Adjustments

Pneumatic masts use compressed air to extend and retract. These masts are well-suited for applications that require quick adjustments and stable support. Pneumatic systems are commonly used for surveillance masts where equipment needs to be adjusted quickly. The key advantage of pneumatic masts is their flexibility and speed. However, the initial cost and maintenance requirements can be higher than manual or electric masts.

Advantages of Pneumatic Masts:

- Quick and flexible adjustment.

- Provides stable support for heavy equipment.

- Excellent for environments that require rapid changes.

Disadvantages:

- Higher operational costs.

- May require compressed air infrastructure.

Hydraulic Masts: Heavy-Duty and High-Load Applications

Hydraulic masts are designed for heavy-duty applications. These masts use hydraulic power to extend and retract, providing significant force for lifting and lowering large, heavy loads. Hydraulic masts are ideal for situations where large cameras, lights, or other equipment need to be supported. While highly reliable and powerful, hydraulic masts come with higher installation costs and maintenance requirements.

Advantages of Hydraulic Masts:

- Capable of lifting and supporting large, heavy loads.

- Easy to operate with powerful extension and retraction.

- Suitable for high-load applications.

Disadvantages:

- High maintenance and repair costs.

- Complex installation process.

Top Mast Products for Public Transport: Specifications & Applications

Now that you have a solid understanding of the various mast materials and power options available, it’s time to explore some of our top-performing products that perfectly align with these considerations. Below, we’ve highlighted four of our best mast products, each designed to meet specific requirements for public transport equipment. These products combine the best of both material selection and power options to deliver optimal performance, durability, and efficiency.

Below, you’ll find four of our premium mast products that meet the rigorous demands of modern public transport systems. These products are designed to offer versatility, durability, and reliability. Check out the detailed specifications below:

Heavy Duty Steel Mast for Light Tower Trailer

Material: High-strength steel

Extended Height: 7.3 meters

Load Capacity: Supports up to 150 kg

Power Type: Manual operation

Applications: Ideal for standard city traffic monitoring and lighting systems, where frequent adjustments are not necessary.

Light Weight Steel Mast for Light Tower Trailer

Material: Lightweight steel

Extended Height: 3-8 meters

Load Capacity: Supports up to 50 kg

Power Type: Manual operation

Applications: Best for urban settings requiring frequent adjustments, providing flexibility in camera angles and light positioning.

Aluminum Mast for Light Tower Trailer

Material: Lightweight aluminum alloy

Extended Height: 5 meters

Load Capacity: Supports up to 20 kg

Power Type: Manual operation

Applications: Best for urban settings requiring frequent adjustments, providing flexibility in camera angles and light positioning.

Aluminum Electric Mast

Material: Lightweight aluminum alloy

Extended Height: 4 meters

Load Capacity: Supports up to 30 kg

Power Type: Electric motor

Applications: Best for urban settings requiring frequent adjustments, providing flexibility in camera angles and light positioning.

How to Choose the Right Mast for Your Needs

Selecting the appropriate mast for your public transport equipment depends on a variety of factors, including the expected load, environment, frequency of adjustments, and budget. Here’s a quick guide to help you choose:

- For Heavy Loads: If you need to support heavy equipment like surveillance cameras, lights, or signage, steel or hydraulic masts are ideal.

- For Frequent Adjustments: If your setup requires frequent adjustments, electric or pneumatic masts are a better option.

- For Corrosion Resistance: If you’re operating in a coastal or humid environment, aluminum or composite materials offer excellent corrosion resistance.

Conclusion: Why Choose Us for Your Mast Needs?

When it comes to selecting the right mast for your public transport system, choosing a reliable, experienced manufacturer is key. At Zhuoyue Metal, we offer a range of high-quality, customizable masts designed to meet your specific needs. Whether you’re looking for a heavy-duty steel mast, a lightweight aluminum option, or an innovative composite design, we have the expertise and resources to deliver. Plus, our masts are designed for easy installation, minimal maintenance, and maximum durability, ensuring long-term reliability for your public transport system.

Contact Us Today

to discuss how our masts can enhance the safety, efficiency,

and overall performance of your public transport infrastructure.